Menu

Menu

MMR Inc. is the Quickest and Most Reliable Gear shop in the US. The MMR facility is fully equipped to Cut up to 3.5 Meter gears In-House.

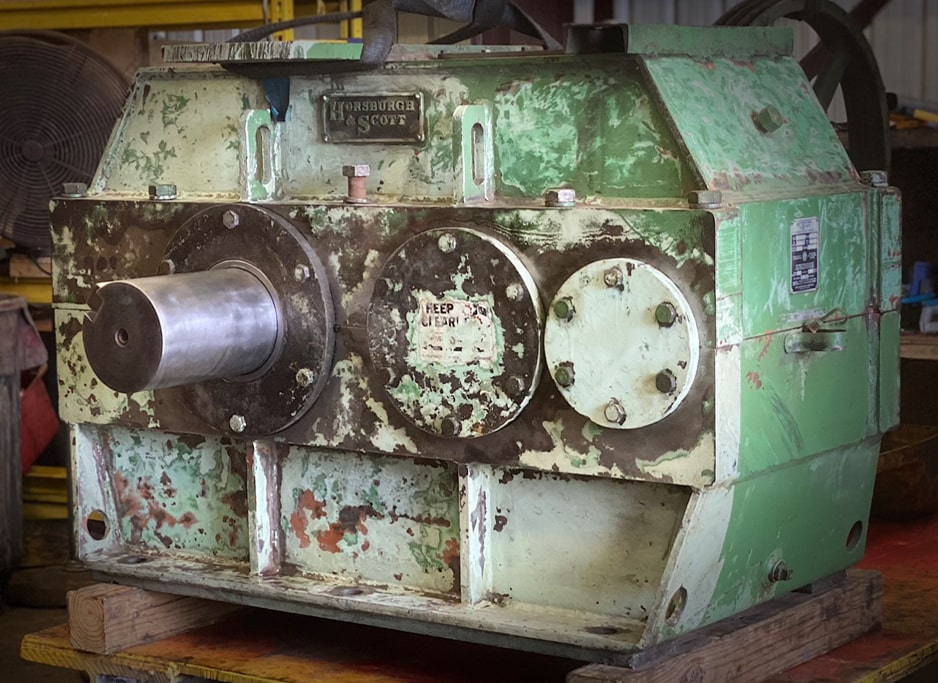

No matter what the brand, if it is a gearbox, we can repair it.

Inspection Report: Each speed reducer received is tagged with a job number, and undergoes a thorough inspection. The inspection report includes all itemized details

When we started Machinery Maintenance Rebuilders in the late 70s repairing and rebuilding gearboxes was our core service. Since then, we have added services and capabilities to apply our experience and expertise to other industries as well.

MMR has rebuilt many gearboxes over the last 30 years, but over the last 3 decades, we have broadened our focus to provide high-quality services to clients in several industries. Large gearboxes are our specialty!

To date, we have repaired and engineered just about every type of gearbox there is and now focus on improving components to equal or improved quality from the original. Our Houston machine shop and gearbox repair facility provide machine services nationally to clients all across the United States.

Web Design Services by Blue Light Labs Inc.